OUR PACKAGING

we have 4 diffrent types of packaging to cover all of your needs , just ask us!

01.

bulk in carton

Bulk packaging refers to packaging products in large quantities or containers. This type of packaging helps optimize cost efficiency and streamline logistics, especially when the dried fruit will be further processed, repacked, or sold in bulk to end consumers.

Cardboard is often used for medium-scale bulk packaging, providing a protective outer layer for dried fruits. The boxes can be sealed or lined with moisture-resistant materials to preserve the product’s quality.

Palletized Packaging: Bulk dried fruit is often palletized (grouped together on a pallet and shrink-wrapped) for easier transportation, storage, and handling. The pallets can hold multiple boxes or bags of dried fruit.

Customization: For businesses that need to repackage the product, bulk packaging offers flexibility in terms of the volume they want to handle. The packaging can also be customized with specific labels, nutritional information, or branding for further processing.

02.

transparent 1kg plastic packaging

All types of dried fruits and vegetables are packaged in 1kg plastic packaging which is put in a mother carton that contains approximately 10 plastic packed dried fruits. Although it differs based on weight and volume of the dried fruits and vegetables.

Materials Used: Polyethylene (PE), polypropylene (PP), or metallized plastic (for barrier protection against moisture, oxygen, and light).

Advantages: Flexible, easy to store, and cost-effective. They also provide excellent protection from contamination and preserve the flavor and texture of dried fruits

03.

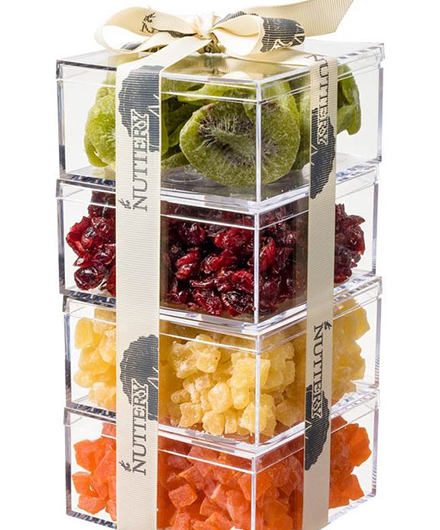

plastic packaging box

These type of packaging is used in both retail and wholesale . plastic packaged boxes are put into a large mother carton to export. For instance , it contains ten or more small boxes in a carton based on dimension of small boxes and cartons . this part is negotiable

04.

metalized plastic packaging

Metalized plastic packaging is a popular packaging solution in the food industry

Flexibility: Metalized plastic can be formed into various shapes and sizes, including stand-up pouches, pillow pouches, and gusseted bags, which offer packaging flexibility based on product needs.

The packaging can be customized for both bulk shipments (where large quantities are packed) and retail-ready formats (individual consumer packages).

Lightweight: Compared to traditional foil or rigid packaging, metalized plastic is much lighter, reducing transportation costs and the carbon footprint of shipping. This is especially advantageous for export and international trade.

Thanks to the variety of color it seems attractive in shelfs of hypermarkets and supermarkets and it comes in handy for retails.

Packaged dried fruits are available from 30gr-1000gr in this style.

05.

Tube packaging

This is a particular packaging and fits customer’s requirement in special markets.

Like European countries.

Tube packaging is a type of products which sells good in shelf of supermarkets.

06.

vaccum sealed packaging

Extended Shelf Life: By removing air, vacuum sealing reduces the rate of oxidation, which is a major cause of spoilage in dried fruits. It helps preserve the product for a longer period, typically ranging from 6 months to 1 year, depending on the type of dried fruit and storage conditions.

Prevention of Moisture Absorption: Dried fruits are sensitive to moisture, which can cause them to become chewy, moldy, or spoil. Vacuum sealing creates a moisture-proof barrier, ensuring that the dried fruit remains in its ideal state.

Maintains Flavor and Nutrients: Oxygen exposure can lead to the loss of volatile compounds that contribute to the flavor and aroma of dried fruits. By creating an oxygen-free environment, vacuum sealing helps retain the natural flavor, color, and nutrients (such as vitamins and antioxidants) in the fruit.

Space-Efficient and Lightweight: Vacuum-sealed packages are typically compact and lightweight, which makes them easier and more cost-effective to ship, especially for bulk or export purposes.

Protection from Contaminants: Vacuum-sealed bags create a protective barrier that prevents contamination from external elements such as dust, dirt, or bacteria, ensuring that the dried fruits remain safe and hygienic.

Prevents Pest Infestation: By removing air, vacuum sealing makes it harder for pests (e.g., insects) to survive in the package, offering an additional layer of protection during transport or storage.

Convenience for Consumers: Vacuum-sealed packaging is typically easy to open and reseal (in some cases), which adds convenience for consumers. The airtight packaging also makes it possible to store the product for a longer period without worrying about spoilage.

Vacuum-sealed packaging is highly suitable for dried fruit exports, especially when shipping over long distances or to international markets. The extended shelf life and protection from external elements ensure that dried fruits reach their destination in optimal condition.

Couldnt find the package you were looking for?

we will always there to help you , giving you the best counseling

even if you are thinking about a fully customized packaging (no matter what, if you can imagine it , we can make it 😀 )pelase dont hesitate to contact us ! we always love to talk to you.